Online 24 hours a day

|

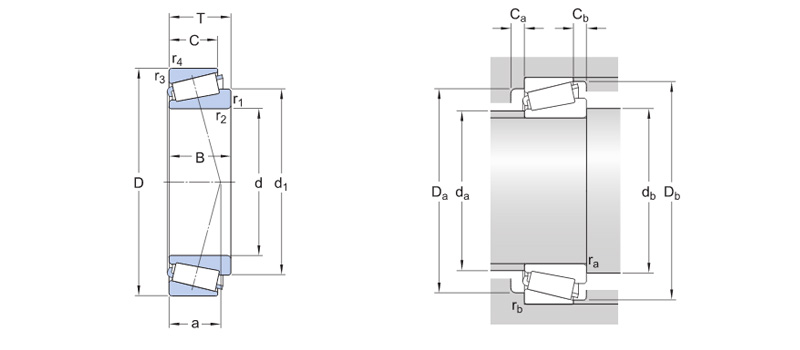

Tapered roller bearing

Collect

Tapered roller bearings belong to the separation type bearings, bearing the inner and outer ring have tapered raceway, its inner ring and a set of tapered rollers by the basket-shaped keep frame envelope into an inner ring assembly, the outer ring can be separated from the inner ring assembly, tapered roller bearings between the outer ring and the inner component is 100 percent can be universal interchangeable use, bearing designed to adapt to the combined load, that is, the simultaneous action of radial and axial load, the raceway extension line The extensions of the raceways intersect at the same point on the axis of the bearing to achieve true rolling and therefore low frictional torque during operation. The axial load capacity of tapered roller bearings increases as the contact angle increases. The size of the contact angle is related to the calculation coefficient, the higher the value, the greater the contact angle. Single tapered roller bearing can bear radial load and single direction axial load, axial load capacity depends on the contact angle, that is, the outer ring raceway angle, the larger the angle, the greater the axial load capacity. When bearing radial load, will produce an axial force, so when another can bear the opposite direction of the axial force bearing to be balanced, compared with angular contact ball bearings, bearing capacity increased, the limit speed is reduced. Tapered roller bearings use the optimized three-convex design method, through the simulation of working conditions, to find the suitable convexity requirements, so as to reduce the contact stress and improve the fatigue life of the bearing; automotive tapered roller bearings using non-standard design and processing methods, can provide better application solutions for automotive users, over the years, has been stable service to domestic and foreign large and medium-sized automotive and accessories enterprises. Features and advantages Low friction The optimised roller design on the retaining edge and the surface finish of the retaining edge promote the formation of a lubricant film, thus reducing friction, heat generated by friction and wear on the retaining edge. Long service life The bearing's basic design bearing and convexity raceway logarithmic raceway shape optimise load distribution along the contact surface, reducing stress peaks at the roller ends and resulting in a long service life. Increased operational reliability Optimised surface treatment of the roller and raceway contact surfaces facilitates the formation of a fluid dynamic pressure lubricant film. Separable and interchangeable That is, the inner ring with roller and cage assembly can be mounted separately from the outer ring. In addition, the separable parts are interchangeable, which facilitates installation, dismantling and maintenance inspection procedures. |